Sandblaster Plans

Make Your Own Sandblaster Exactly the way you want it With a better design & Save Money!

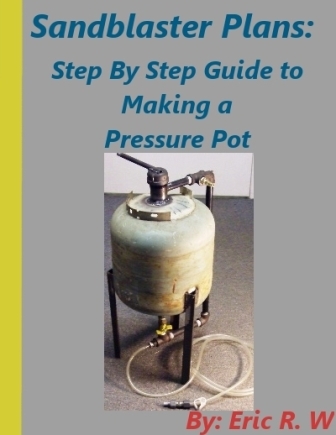

My newest sandblaster plans show you step by step how to make your own pressure pot blaster. Each step of the way, I provide photos for each section and a detailed explanation of what to do.

These are my own uniquely designed and configured sandblaster plans which shows how to build with widely known parts available at local hardware stores. I also show close up photos of all the parts needed and sources of where you can get them inexpensively.

Part 1: Shows Exactly How to Assemble Tank

The pressure pot sandblaster can be made out of old grill size propane tanks. I explain how to do this safely and places to get them for free. (Please be careful with this and follow my advice in the plans) Then the steps show me assembling each specific part onto the tank.

Part 2: Making My Unique Nozzle & Hose Assembly

The second part of my plans shows you how to make my unique nozzle assembly that lasts much longer than other nozzles. Its also variable so you can control the amount of abrasive blasting from your finger tips. A third benefit, its very inexpensive and very easy to make- you will be surprised. These are excellent for etching, sandcarving, and for sandblasting inside cabinet booths.

This part also shows my self tested components and where to get them online all in one place. Some of these components are in a high abrasive area so they need to be steel or iron. Most hardware stores only carry the brass ones which will wear out very quick. You can click the links to my favorite discovered sources.

But that’s not all! 5 Bonuses Included

Since you are supporting the continuation of my site and purchasing today, I am also adding on 5 BONUSES. Over the past few years, a lot of my subscribers and visitors have been asking me much desired questions that these bonuses explain. For ordering today, I will attach the following bonuses:

Bonus 1: Matching Nozzle ID Size with Air Compressor:

This bonus explains how to pick a good ID bore size for your nozzle that is supported by your air compressor. This is essential to know about. Includes an industry referenced chart which helps you find a air compressor to buy for your particular application. Included information about PSI & CFM air requirements for multiple different nozzle sizes. Now shows calculated specs for even smaller 1/16″ and 3/32″ nozzles!

Bonus 2: What Abrasive Grit Size Can Fit Through My Nozzle?

Explains the rule of thumb on how course of an abrasive grit will work with your nozzle bore size and a quick reference chart.

Bonus 3: Air compressor Types Guide

Explains the different types and sub-types of compressors used in the industry. Topics included Fuel & Electric powered and one stage & two stage. Shows pictures of each type and disadvantages for each.

Bonus 4: New Abrasive Problems Guide

This is my latest discovery of why a lot of people are still having abrasive flow problems. Along with a diagram showing you what the problem is inside and how to fix it with a simple solution.

Bonus 5: Sandblasting Safety Guide:

A much needed industry guide to talk about safety, silicosis prevention, and safety gear with sources.

Download my sandblaster plans and extra bonuses today for Only $17!

Please note that this is a temporarily reduced price and will be raised up very soon. Get them today for only $17 before the price goes back up to the original set price.

The plans are available in a down-loadable PDF file. Acrobot Reader is required to open and view the file. If you don’t have it, you can download it free on the internet which I will show you.

There are no shipping fees and you will be automatically re-directed to a webpage where the PDF file can be downloaded.

Instantly download your copy by clicking the button below:

100% Risk Free Guarantee:

If the plans didn’t provide you any helpful information and you aren’t 100% satisfied with the Ebook, then send me a quick email and I’ll happily refund you in full within 30 days. This way you have no risk in getting my plans!

Hi Eric. First I want to say, what an awesome web site you have here! My question about the plans, do they show information about building a wet blaster ” slurry blaster” ? I want to build a mobile unit similar to the one mmlj company has on their web site. Thanks again for this awsome site.

@ Troy, yeah I started building and experimenting with a home made one last Fall, but haven’t been successful yet. I wrote a post on it though which explains the mechanics of how it works, along with other commentators great ideas here: https://www.sandblasterinfo.com/dustless-sandblasting/

That is a good starting point.

Do you sell Abrasives? If you don’t can you put me in touch with those that do? Looking for Alum oxide mainly. Thanks for all your hard work and research. Mike Daniels Captain, Merchant Marines

Do the instructions for making this require any welding?

@Kathy, yes it requires welding, but it is very possible to forgo this through a combination of making your own threads for the pipes to fit in the tank along with a combination of JB Weld as a sealant. You could probably find a thread tap fairly inexpensively. Although this would mostly work fine, I have never tested the max pressure it could hold and would be best not to use too much pressure through that method. It would be best to use a safety release valve with it.

Eric, I work with certified money orders, for payments, where can send one if I may. Dean

have any plans on something similiar to the dustless blasters

need plans on something like dustless blaster d225

Hi Eric,

I wish I could buy your DIY and proven / tested sandblaster plans. May make payment for the PDF Plans through money order, say by Western Union? I do not have Mastercard/Visa/American Express/Discover/ and Paypal.

Thanks .

Edgardo

Saludos Eric, por favor deseo informe de los planos de tu arenadora, de que capacidad es, confirmame el costo….

Atte.

Edwar Lostaunau

Hi Eric, I do have a PAB blaster system. I am in the process of wanting another pot but with only one 1/4″ gun. As a pab user there are some issues with the gun & the pot. I don’t see any metering /adjustment valves for your pot. Can you give me some more insight into yours before I commit to purchasing your plans? Thanks Kevin.

I wonder if you have looked into dustless blasting? And could you design a pressure pot that used both water and air pressure to do the work.

@Matt, you definitely could. I started making and testing one a few years ago but never got around to finish it. I provide some info in the link listed in another comment above.

Hi. I have an art studio, and I use to work in the monument design industry designing headstones, memorials, etc.. its been a long time. Now I have an art studio and have been taking orders for hand-painting pet memorials on natural river rock … round, oval, smooth stone

What I need to know is… What kind of abrasive do I need.. Will this sandblaster stand up to it? and I forget alot of this.. like I said.. has been years out of the industry.. But.. what cfm @ ? do I need. I would like to be able to offer my customers the ability to have their pets names, a saying, etc.. sandcarved/engraved to the back of the stone. I also have been approached many times about sandcarving a boulder

Please let me know! Am anxious to hear from you!

Thanks so much!!

Hello Eric

I am a fan of Dustless Blasting and just wondering if you could share some knowledge on how to built it.